The MGA With An Attitude

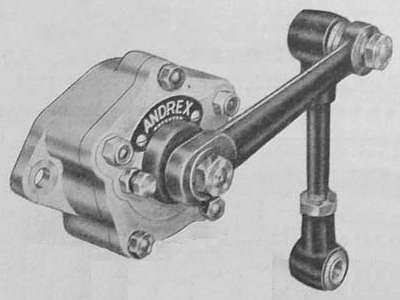

ANDREX Friction Shock Absorbers - FS-125

This is a rare factory option that was sometimes installed on MGA 1500 cars and early Twin Cam cars. I do not know if it was ever used on 1600 or 1600-MK-II cars. It cannot be used when a front sway bar is installed, because they occupy some of the same space on the chassis.

These days we are generally familiar with use of a sway bar, and this is discussed extensively in other articles. Before the sway bar was available on the MGA you could install these Andrex friction shocks as a supplement to the original Armstrong hydraulic shocks. There is more to this science than simply increasing damping rates, because hydraulic and friction shocks have different operating characteristics.

|

Andrex dampers fitted to an MG TD

Andrex dampers fitted to an MG TD

|

Andrex dampers fitted for Le Mans

Andrex dampers fitted for Le Mans

|

Suspension springs have the task of carrying the vehicle weight while allowing some motion in the suspension to accommodate road surface irregularities. Springs have a characteristic "spring rate", meaning the force changes with height. This affords some control over the amount of pitch and roll in the chassis. Stiffer springs (higher spring rate) will reduce body roll and shorten steering response time. Softer springs will reduce harshness of ride with bumps. Different spring rates front and back can redistribute chassis weight proportionately among the tires as the chassis rolls somewhat in cornering, which in turn can modify oversteer or understeer character.

Suspension springs have the task of carrying the vehicle weight while allowing some motion in the suspension to accommodate road surface irregularities. Springs have a characteristic "spring rate", meaning the force changes with height. This affords some control over the amount of pitch and roll in the chassis. Stiffer springs (higher spring rate) will reduce body roll and shorten steering response time. Softer springs will reduce harshness of ride with bumps. Different spring rates front and back can redistribute chassis weight proportionately among the tires as the chassis rolls somewhat in cornering, which in turn can modify oversteer or understeer character.

Sway bars (actually anti-sway bars) are springs that redistribute chassis load from side to side as the body rolls. These can be used to reduce body roll, improve steering response, and redistribute weight among the tires to affect handling. A sway bar is often easier to install or adjust compared to changing suspension springs, and it has much less (detrimental) affect on ride comfort. Presence of the sway bar can allow use of softer suspension springs.

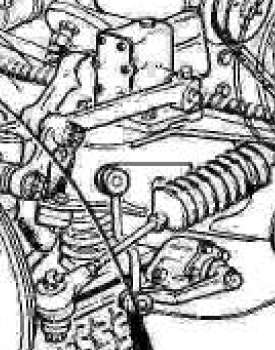

Andrex damper bracket on frame --

Andrex damper removed to install sway bar

|

Shock absorbers are used to dissipate energy in the form of heat as the suspension and chassis move, much as brakes dissipate energy as heat to slow the car down. Hydraulic shocks do this by pushing oil through small orifices to generate heat as the hydraulic pressure drops (viscous liquid friction). They will have small resistance with slow motion so they can give soft ride with small bumps and slow body roll. They have increasing resistance with increasing motion speed in the suspension so they can be more effective on larger bumps. And they (usually) have a fixed maximum resistance at high speed due to an internal pressure relief valve. Friction shocks will (usually) have a fixed resistance over full travel regardless of speed, and most will be adjustable for resistance.

Shock absorbers are used to dissipate energy in the form of heat as the suspension and chassis move, much as brakes dissipate energy as heat to slow the car down. Hydraulic shocks do this by pushing oil through small orifices to generate heat as the hydraulic pressure drops (viscous liquid friction). They will have small resistance with slow motion so they can give soft ride with small bumps and slow body roll. They have increasing resistance with increasing motion speed in the suspension so they can be more effective on larger bumps. And they (usually) have a fixed maximum resistance at high speed due to an internal pressure relief valve. Friction shocks will (usually) have a fixed resistance over full travel regardless of speed, and most will be adjustable for resistance.

Offset arm and offset link as used on MGA

Andrex dampers on rear of a MG TD

|

When hydraulic shocks with pressure relief move at high speed (as with harsh road bumps) they act a lot like friction shocks with constant force over full travel (perhaps different max force in the return direction), effectively putting the "brakes" on suspension travel. But with slower suspension travel speed (as with body roll during cornering) the hydraulic shocks don't do much (unless they may be adjusted to be very stiff and harsh). This is where friction shocks can give some advantage. Friction shocks can be set to provide moderate resistance that can be effective at damping out low speed body roll and low speed road bumps. As such the friction shocks have some cross over characteristics of sway bars, springs and hydraulic shocks. Some people find these useful for suspension tuning, especially for sudden left/right steering changes in the absence of a sway bar. It is like having a stiffer sway bar for sudden steering maneuvers, and better low speed damping for undulating road surface.

When hydraulic shocks with pressure relief move at high speed (as with harsh road bumps) they act a lot like friction shocks with constant force over full travel (perhaps different max force in the return direction), effectively putting the "brakes" on suspension travel. But with slower suspension travel speed (as with body roll during cornering) the hydraulic shocks don't do much (unless they may be adjusted to be very stiff and harsh). This is where friction shocks can give some advantage. Friction shocks can be set to provide moderate resistance that can be effective at damping out low speed body roll and low speed road bumps. As such the friction shocks have some cross over characteristics of sway bars, springs and hydraulic shocks. Some people find these useful for suspension tuning, especially for sudden left/right steering changes in the absence of a sway bar. It is like having a stiffer sway bar for sudden steering maneuvers, and better low speed damping for undulating road surface.

Some modern shock absorbers may have variable damping over travel distance and may be adjustable for maximum damping force. Some vintage hydraulic shocks can also be adjustable or may be modified to provide adjustability. A sway bar also provides roll control. These together can provide enough advantages to remove most of the incentive to use friction shocks as a supplement. There may also be an overall cost advantage to incorporating more functions into the hydraulic shock to eliminate need for the friction shocks. As such the friction shocks are seldom used on newer cars. Some "updating" of suspension parts (like adding a sway bar) may also negate use of the friction shocks on vintage cars. Even so, some people may want to retain use of the friction shocks for historical reason on a vintage car, or for use in certain regulated vintage racing classes.

|