The MGA With An Attitude

LEAF SPRING Modification -- RS-104A

Beware from the start that this is a lesson in what NOT to do to a leaf spring.

On 10 January 2010, someone who shall remain nameless wrote:

"I tried something with the [too tall] aftermarket leaf springs resulting in lowered ride height (the rebound straps actually fit). I removed the U-bolts on one side, removed the anchor bolt, removed the 17 inch leaf and discarded it. I moved the two small leafs from the bottom of spring to the top of the spring, refit the U-bolt, then duplicated this on the other side. This lowered the rear by aprox. 3/4 inch. This greatly improved handling and driveability".

My first reaction to this was, "Oh gawd, don't do it". I would never be so bold as to try this on a road going car for fear of overstressed and future broken springs. You have just reduced the spring rate and dramatically increased stress on the remaining load bearing leafs. I would never recommend for anyone to do it in this manner.

This is a 6-leaf spring. The bottom plate is not a spring leaf but is a load spreading part designed to relieve and remove stress from the center point on one or two leaves immediately above it. Each leaf, as short as it is, also serves to relieve stress load on the longer leaf above it. A leaf spring will have relatively low bending load near the ends and progressively higher bending load closer to the center. The way the leaves are stacked there are more layers of steel in the center to take the higher bending load there, resulting in more even stress distribution throughout the entire structure.

If I read the description right, he removed the bottom plate and leafs 6 and 5, then installed the bottom plate and leaf 6 on top of the stack. Installing two short pieces on top lowers the car by .44" simply due to the displacement of space, but these two pieces will do nothing to support the load. You can achieve the same lowering effect by simply adding a 7/16" thick lowering block between the spring and axle without changing the spring (but use 1/2" longer U-bolts). You now have only 4 leaves supporting the load rather than 6, and there will be almost no center support for leaf #4.

Since the plates are all same thickness, you have increased the bending load and stress near center of the remaining 4 load bearing leaves by 50%. This is the stress equivalent of putting 450 pounds of added weight in the boot directly over the rear axle. With 50% increase of stress on the spring you should expect a dramatically shortened life for the leaf springs. That is, they might sag an inch after 5 or 10 years (rather than 100 years), and they might break after a few years of use (rather than never in a hundred years). I don't know what else to say other than good luck, and maybe send a follow-up report some years later after you see how it works out in the long run. Maybe you won't live long enough to see it sag, and maybe you won't drive it enough to break a spring, but you could eventually become the DPO in a big way (to the next owner).

Note that when fully laden (to average operational vehicle weight) the top leaf should be flat, straight, with the axle mount in center at same height as the end eyes. This allows the spring to take a large lateral loading during cornering with very little sideways deflection or twisting (and minimum stress). This is of course assuming that it has the correct load and stress in this condition, which requires that it must start with the correct free height (unladen). In your case, if the spring ends up loaded to be somewhere close to flat, then it would have started with higher than normal free height (you did say it was too tall to begin with), and is taking more than the normal amount of deflection. That's where the increased stress comes from.

I had a pair of those too-tall leaf springs on my car for a few months in 1997, mostly during the Alaska trip. After just one competitive autocross date they came off and were sold at the next swap meet. As you likely noted, handling was absolute crap with the tail end too high. I rebuilt the original springs (without needing to be re-arched), and they are still on the car now with 360,000 accumulated miles (not counting 20,000 miles on the too-tall springs).

Race car preparation sometimes calls for a slight modification of the original stock configuration rear springs. Some people might remove the 2nd leaf above the bottom plate (leaf #5). This is done to reduce the load capacity and spring rate a bit when the car is lightened to the limits for racing and will never carry any load in the boot. Otherwise lowering rear ride height is done with lowering blocks between spring and axle housing. This is to avoid screwing up the spring characteristics. This is commonly accompanied by installation of shorter and higher rate front springs and a fat front anti-sway bar, both of which reduce body roll, which subsequently reduces loading on the rear springs.

|

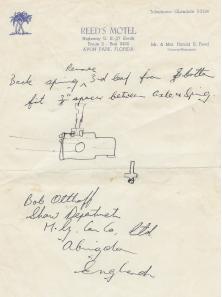

This interesting note was supplied by Edward Vandyk in the UK.

It was penned by Bob Orthoff, written on stationary from a hotel in Avon Park, Florida (USA), just down the road from Sebring Florida. It is instruction for the desired modification of the leaf spring for a race car.

I believe that "third leaf from the bottom" is referring to what I show as leaf number 5 in the illustration above, assuming they counted the bottom plate as a leaf (but I could be wrong).

|