The MGA With An Attitude

MGA Guru Is GOING MOBILE - (May 16 - May 31, 2020)

Saturday May 16, 2020:

Saturday May 16, 2020:

Thought I might be off to do some mechanical work today, but apparently not. But I did have time to post up a new tech page for Positive Crankcase Ventilation for the MGA Twin Cam engine.

Sunday May 17, 2020:

More discussion on the pros and cons of installing a PCV valve on a vintage car that did not originally have one.

Answering tech questions (holding a hand) for assembling an MGA windscreen, which is always tricky stuff for a first timer. Answering tech questions (holding a hand) for assembling an MGA windscreen, which is always tricky stuff for a first timer.

Trying to talk someone out of retrofitting a rubber rear crankshaft seal on another MGA. Trying to talk someone out of retrofitting a rubber rear crankshaft seal on another MGA.

Fielding a tech question on de-bugging dysfunctional turn signals on the MGA, and another one on bleeding the clutch slave cylinder (common stuff). Fielding a tech question on de-bugging dysfunctional turn signals on the MGA, and another one on bleeding the clutch slave cylinder (common stuff).

Monday May 18, 2020:

Updated a web page on anti-sway bars to show modification of the early front spring pans to later issue configuration to be used with (or without) the sway bar links.

Updated a web page on anti-sway bars to show modification of the early front spring pans to later issue configuration to be used with (or without) the sway bar links.

Investigation of a Car No. tag on a CKD MGA assembled in South Africa. It is late model 1600-MK-II, but the Car Number is stamped similar to an earlier production car. Maybe the assemblers in South Africa never got around to changing the number format like the folks in England did. Good discussion though, because I don't have a lot of information about CKD's in South Africa, so this should add to the public information. Investigation of a Car No. tag on a CKD MGA assembled in South Africa. It is late model 1600-MK-II, but the Car Number is stamped similar to an earlier production car. Maybe the assemblers in South Africa never got around to changing the number format like the folks in England did. Good discussion though, because I don't have a lot of information about CKD's in South Africa, so this should add to the public information.

Put together a parts order for a friend, something more than $500, mostly for rear axle, suspension and brake parts for his MGA project (same car we have been working on during the past several weeks). Put together a parts order for a friend, something more than $500, mostly for rear axle, suspension and brake parts for his MGA project (same car we have been working on during the past several weeks).

Posted a new *.pdf file for BMC standard part numbers for PoziDriv screws, sort of a supplement for the Fastiner Decode Booklet. Posted a new *.pdf file for BMC standard part numbers for PoziDriv screws, sort of a supplement for the Fastiner Decode Booklet.

Tuesday May 19, 2020:

Discussing how to R&R the MGA Twin Cam engine timing cover without removing the engine from the car. Pretty tight access for some of the lower bolts, but we think it can be done. Fodder for a possible future tech article.

Restaurants still on lock down, so Chicagoland MG Club is planning a virtual club meeting on the internet using Zoom Meeting, hopefully next Monday evening. Restaurants still on lock down, so Chicagoland MG Club is planning a virtual club meeting on the internet using Zoom Meeting, hopefully next Monday evening.

A little follow-up business from May 7, now posting pictures of tools and how-to notes for modifying the Twin Cam brake master cylinder cap (aftermarket part) to look more like the original issue part. A little follow-up business from May 7, now posting pictures of tools and how-to notes for modifying the Twin Cam brake master cylinder cap (aftermarket part) to look more like the original issue part.

Had a nice chat with a bloke in Las Vegas who recently inherited an MGA from his father, and is now beginning a full restoration project.

Wednesday May 20, 2020:

Had an email "conversation" about dysfunctional turn signals in an MGA 1500. I'm sure the correct diagnostic and fix information is on my web site, but still a bit confusing for someone who hasn't been there before.

Thursday May 21, 2020:

Good that Moss Motors is open and shipping again (although they are a little behind). They also opened up their (delayed) annual Upholstery Sale for the next 30 days. We finally ordered some parts that should arrive early next week, including a second try on the center exhaust hanger.

Received a report of an MGA windscreen assembly problem. Apparently some tapped holes in the internal brass tapping strip (new parts) do not align properly with screw holes in the original frame. Will be checking into this issue soon. Received a report of an MGA windscreen assembly problem. Apparently some tapped holes in the internal brass tapping strip (new parts) do not align properly with screw holes in the original frame. Will be checking into this issue soon.

Friday May 22, 2020:

Friday May 22, 2020:

Added a CAD drawing for radio speaker grill which can be used to generate an output file for water jet or laser cutting to make the parts (if you have the right software to do it).

Saturday May 23, 2020:

Making a new tech page for R&R of the timing cover on a Twin Cam engine (in the car). Had in mind to draw up a special "Phillips wrench", but got hung up trying to draw the tip of a Phillips srew driver. Sometimes trivial stuff can kill a lot of time.

Tech question about bushing throttle shafts in SU carburetors, 660 bronze vs. Oilite vs. Delrin bushings. Flip a coin, mechanic's choice. Tech question about bushing throttle shafts in SU carburetors, 660 bronze vs. Oilite vs. Delrin bushings. Flip a coin, mechanic's choice.

Then I got carried away doing calculations for trigger time and duty cycle for an air tool given a rather small air compressor and high consumption air tool (bad combination). Then I got carried away doing calculations for trigger time and duty cycle for an air tool given a rather small air compressor and high consumption air tool (bad combination).

Sunday May 24, 2020:

Considering a report of an odd intermittent fading brake pedal problem, usually works, but sometimes goes to the floor, and then recovers and gets back to normal operation. Seems to be temperature sensitive (but that could be a coincidence). Suspect something variable in the master cylinder, but solved yet.

Monday May 25, 2020:

Today's problem was how to get a stuck piston out of a brake caliper. I just discovered I no longer have my magic bolt with a Zerk fitting in it, so need to make another one, Just a 3/8-24-UNF bolt, drill an axial hole through it, tap a #10-32-UNF thread, and install a straight in Zerk fitting. Killed some time taking inventory of taps and dies in my possession, and making plans to buy some more. Killing too much time searching the net. Need to got to a good hardware store (not H.F.).

Tuesday May 26, 2020:

Friend in Indiana has been working on getting a long stagnant MG back on the road, for a long time. Finally got it out for a test drive, discovering a real gusher of an oil leak somewhere at rear of the engine. Not sure exactly where, beginning to worry about rear crankshaft scroll seal being badly damaged.

A friend in St. Lambert, Quebec, Canada has a leaky rear hub. We all know how to change parts, but the discussion is more in the line of determining how much needs to be done (and how much maybe not). A friend in St. Lambert, Quebec, Canada has a leaky rear hub. We all know how to change parts, but the discussion is more in the line of determining how much needs to be done (and how much maybe not).

Got into a good hunt for bullet connector crimping tool (for someone else, not me). Pricing all over the place, not my issue, but also mostly out of stock. Vendors seem to put their own inventory part number on this tool, even though they may all have a common source. Would be nice to know who actually makes it. Got into a good hunt for bullet connector crimping tool (for someone else, not me). Pricing all over the place, not my issue, but also mostly out of stock. Vendors seem to put their own inventory part number on this tool, even though they may all have a common source. Would be nice to know who actually makes it.

Start of a discussion on a slow cranking starter on an MGA Twin Cam (but could just as well be any car). Start of a discussion on a slow cranking starter on an MGA Twin Cam (but could just as well be any car).

Wednesday May 27, 2020:

More discussion on the bullet connector crimping tool. Found one at a motorcycle shop, but twice the price expected. Keep looking.

More discussion about the gusher oil leak in Indiana. Sounds like way too much oil to be a crankshaft rear leak. Removed the sump. Bingo, missing a primary pressure plug in the bottom of the engine block over the sump gasket, with pump pressure pushing oil out past the gasket. Seriously bad screw-up by the engine builder, but at least it's pretty easy to fix with minimal cost. More discussion about the gusher oil leak in Indiana. Sounds like way too much oil to be a crankshaft rear leak. Removed the sump. Bingo, missing a primary pressure plug in the bottom of the engine block over the sump gasket, with pump pressure pushing oil out past the gasket. Seriously bad screw-up by the engine builder, but at least it's pretty easy to fix with minimal cost.

Receive some parts from Moss today, mostly small carburetor parts to replenish inventory. But included was a second copy of the erroneous hanger. Supposed to be a center exhaust hanger (rubber and metal), correct part number, but wrong part in the bag. Looks like a rear exhaust bracket for a rubber bumper MGB. Okay, one phone call and they will send me another one. However, they sent it to my "official" home address in Sandwich, Illinois when I am in Columbus, Ohio. Oh well. Daughter can forward it to me, or maybe hold onto it until I get back in the neighborhood again. Receive some parts from Moss today, mostly small carburetor parts to replenish inventory. But included was a second copy of the erroneous hanger. Supposed to be a center exhaust hanger (rubber and metal), correct part number, but wrong part in the bag. Looks like a rear exhaust bracket for a rubber bumper MGB. Okay, one phone call and they will send me another one. However, they sent it to my "official" home address in Sandwich, Illinois when I am in Columbus, Ohio. Oh well. Daughter can forward it to me, or maybe hold onto it until I get back in the neighborhood again.

Thursday May 28, 2020:

Had an extended discussion about checking out a prospective car before purchase. I do that sometimes, if it happens to be in my neighborhood. More often I start by giving it a really good grilling by looking at any available pictures. My notes after the pictures is sometimes enough to kill the consideration instantly with no further fuss and no inspection required. Saves a lot of time.

Spent some time discussing "bad grounds" and debugging of lighting circuits. Simple standard stuff for me, but often puzzling for an amateur new to the game. These questions keep me reviewing my web site to see if there isn't already enough information there. Beginning to think that basic electrical debugging could use a whole series of videos (but so far videos are not my strong suit). I could imagine rigging up some simple circuits and doing an electrical tech session at some national car show. Spent some time discussing "bad grounds" and debugging of lighting circuits. Simple standard stuff for me, but often puzzling for an amateur new to the game. These questions keep me reviewing my web site to see if there isn't already enough information there. Beginning to think that basic electrical debugging could use a whole series of videos (but so far videos are not my strong suit). I could imagine rigging up some simple circuits and doing an electrical tech session at some national car show.

Friday May 29, 2020:

Finished a drawing (and a new tech page) for a special Phillips wrench to access a hidden screw head on a Twin Cam engine mount.

Got a tech question about R&R of the crankshaft spigot bushing. I thought I had it well covered, but something turned up where two engines somehow have different position for the bushing. I suspect one of then was pushed in too far. Got a tech question about R&R of the crankshaft spigot bushing. I thought I had it well covered, but something turned up where two engines somehow have different position for the bushing. I suspect one of then was pushed in too far.

More discussion on high resistance connection for heavy current battery and starter and ground cables. Believe it or not,anything more than a few milliohm resistance in a bolted cable joint can play havoc with cranking current in a low voltage circuit. More discussion on high resistance connection for heavy current battery and starter and ground cables. Believe it or not,anything more than a few milliohm resistance in a bolted cable joint can play havoc with cranking current in a low voltage circuit.

Discussing steering rack input pinion shaft seals. The felt seal here is a pain. May be time to measure the glands and look into a rubber O-ring. Discussing steering rack input pinion shaft seals. The felt seal here is a pain. May be time to measure the glands and look into a rubber O-ring.

Saturday May 30, 2020:

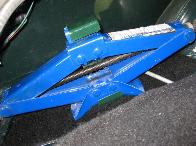

Posted a new tech page showing a securing clip for a diamond jack in the boot of an MG.

Solving a problem with slow cranking starter on a Twin Cam, cleaning cable connections and looking at resistance in the starter switch and battery cut-off switch. Standard stuff, and common bad parts. Solving a problem with slow cranking starter on a Twin Cam, cleaning cable connections and looking at resistance in the starter switch and battery cut-off switch. Standard stuff, and common bad parts.

Chatting about long pedal travel for a drum brake car, needing to adjust brake shoes and bleed out the air (nothing new). Chatting about long pedal travel for a drum brake car, needing to adjust brake shoes and bleed out the air (nothing new).

Take a long pause to see Crew Dragon launch on a Falcon 9 with two test pilots destined to dock with the ISS. And the booster landing on the drone ship for return and reuse. Good feelings all around. Take a long pause to see Crew Dragon launch on a Falcon 9 with two test pilots destined to dock with the ISS. And the booster landing on the drone ship for return and reuse. Good feelings all around.

Sunday May 31, 2020:

Off to visit Marc Chapman in Westerville, OH today to do a little work on the rear axle asssembly for his MGA 1600-MK-II. Marc had already cleaned everything and painted the axle housing, brake backing plates and rotating bearing hubs, so we were off to a good start. Marc's father also dropped in to lend a hand He used to own an MGA, back in the day.

We took after the differential first, wanting to change the front seal and adjust the input bearing shims for slight preload. The assembly took a short trip down the street to have a friend loosen the front nut, since we didn't We took after the differential first, wanting to change the front seal and adjust the input bearing shims for slight preload. The assembly took a short trip down the street to have a friend loosen the front nut, since we didn't

have an air impact wrench handy. Then the front yoke needed some encouragement to come out, and the front bearing was even more stubborn. So we removed two main bearing caps from the back to remove the ring gear and differential gears assembly. That cleared the way for tapping on the front of the input shaft to drive it out the back, leaving the front roller bearing in the housing.

have an air impact wrench handy. Then the front yoke needed some encouragement to come out, and the front bearing was even more stubborn. So we removed two main bearing caps from the back to remove the ring gear and differential gears assembly. That cleared the way for tapping on the front of the input shaft to drive it out the back, leaving the front roller bearing in the housing.

Then it was easy enough to separate the shims we found inside, two tens and a three (0.023 inch total). The final

adjustment was just to remove the 0.003 shim and put the two 0.010's back in for 0.020 inch remaining stack. Pretty quick, and we lucked out that way, not needing to use any of the new shims recently purchased. Once it had the proper preload on the bearings, just remove the front yoke once more to install the front seal, put the dust cover back on the yoke, and get the front nut torqued up. Even easier to reinstall the ring gear and differential assembly with two bearing caps, 4 thin hardened steel flat washers, four lock washers and nuts in back. Then it was easy enough to separate the shims we found inside, two tens and a three (0.023 inch total). The final

adjustment was just to remove the 0.003 shim and put the two 0.010's back in for 0.020 inch remaining stack. Pretty quick, and we lucked out that way, not needing to use any of the new shims recently purchased. Once it had the proper preload on the bearings, just remove the front yoke once more to install the front seal, put the dust cover back on the yoke, and get the front nut torqued up. Even easier to reinstall the ring gear and differential assembly with two bearing caps, 4 thin hardened steel flat washers, four lock washers and nuts in back.

We soon had assembled new seals and bearings in the hubs, bolted up the brake backing plates, installed the hubs and halfshafts with the splined hubs for wire wheels. We were in process of installing new slave cylinders when we discovered a small discrepancy. We soon had assembled new seals and bearings in the hubs, bolted up the brake backing plates, installed the hubs and halfshafts with the splined hubs for wire wheels. We were in process of installing new slave cylinders when we discovered a small discrepancy.

The new cylinders with Unipart packaging (made in UK) had different end caps with only a single small The new cylinders with Unipart packaging (made in UK) had different end caps with only a single small

tab to align the brake adjuster mask, and no inboard flange to align against the backing plate. Not sure how old these parts are, as they came from inventory procured from someone else. After due consideration, we salvaged the end caps from the old cylinders to install on the new ones. That allowed us to go ahead with installing the new brake shoes and getting the drums back on.

tab to align the brake adjuster mask, and no inboard flange to align against the backing plate. Not sure how old these parts are, as they came from inventory procured from someone else. After due consideration, we salvaged the end caps from the old cylinders to install on the new ones. That allowed us to go ahead with installing the new brake shoes and getting the drums back on.

That immediately revealed another issue with the new brake shoes being too small (end to end) so the adjusters ran at least a dozen notches up the ramp before the shoes touched the drums. The new shoes were a tad shorter than the old shoes that were about 1/3 worn. We know what that means, just a few thousand miles down the road there will be no rear brakes. So this was time to call it a day while we consider options for welding up the new shoes, or welding shims onto the adjuster masks, or re-using the old shoes after cleaning them. Everywhere we turn these days we find more bad parts and waste more time having to deal with them. That immediately revealed another issue with the new brake shoes being too small (end to end) so the adjusters ran at least a dozen notches up the ramp before the shoes touched the drums. The new shoes were a tad shorter than the old shoes that were about 1/3 worn. We know what that means, just a few thousand miles down the road there will be no rear brakes. So this was time to call it a day while we consider options for welding up the new shoes, or welding shims onto the adjuster masks, or re-using the old shoes after cleaning them. Everywhere we turn these days we find more bad parts and waste more time having to deal with them.

|