The MGA With An Attitude

| MGAguru.com |

|

MGAguru.com |

MGA Guru Is GOING MOBILE - (February 1 - February 15, 2025)

Saturday - February 1, 2025:

Interesting start. 1.4 mile drive,and just pulling into our morning breakfast stop when we heard "ker-plop, ker-plop, ker-plop". Not another flat tire? No, not yet. Pretty sure it was the left rear car tire, hoping it wasn't some carcass failure blister in the tread. Ran my hands around the tire and found the problem. It was a short hex head sheet metal screw stuck in a thick part of the rubber tread,only about two threads deep, so not deep enough for a puncture through. Pulled it out easily with my fingers and got the picture.

Digging into the racing Rabbit's dash panel, not much of the original wiring harness left, no harness cover, some wires removed, some new wires added, don't know if it will ever be wrapped again. Finally getting the new digital/analog water temperature gauge working. There is this nice butane torch, like a giant cigarette lighter, specifically intended for installing heat shrink tubing. The dang thing even has a bottle opener built into one side, a real redneck tool to make you smile. Drill a hole, install a Rivnut, use a long screw to fasten the dash panel back in place.

Digging into the racing Rabbit's dash panel, not much of the original wiring harness left, no harness cover, some wires removed, some new wires added, don't know if it will ever be wrapped again. Finally getting the new digital/analog water temperature gauge working. There is this nice butane torch, like a giant cigarette lighter, specifically intended for installing heat shrink tubing. The dang thing even has a bottle opener built into one side, a real redneck tool to make you smile. Drill a hole, install a Rivnut, use a long screw to fasten the dash panel back in place.

Bit of diversion while we try to fix a drill chuck that hangs up when tightened only half way. Wanting to remove the chuck, a quick search on the internet finds an instruction video saying the internal screw has left hand thread, turn right to loosen. It turned out the screw was already loose and half way out. Turn left to screw it back in and tighten, and the chuck was working again. Wonders never cease.

I think we can salvage the scarfed up chrome exhaust tip that was dragging on the pavement. Drill out the pop rivets and hammer out the damage at the output end. The painful job was to re-hang the exhaust pipe, having to crawl around the pavement under the car again. Getting creative, bend up a new steel strap and drill holes to attach this thing under the floor, well up inside the tunnel.

Needing to extend the pipe a bit to position the outlet down turn just ahead or the rear axle cross member. Get the new slip joint extension pipe, cut to length and weld it all together.

Final test fit, slight interference, raise a brake pipe and add a P-clip to hold that in place. Take the pipe to the bench to weld the exhaust tip, then back under to attach the rear hanger clamp. Drag the welder cables underneath to weld he front flex pipe to the header pipe so that 'joint will never fall apart again. And thar it is, thinking you could hang another car on that pipe now, all tucked up nicely inside the tunnel, and you couldn't even scrape that pipe on a trailer ramp now.

Final test fit, slight interference, raise a brake pipe and add a P-clip to hold that in place. Take the pipe to the bench to weld the exhaust tip, then back under to attach the rear hanger clamp. Drag the welder cables underneath to weld he front flex pipe to the header pipe so that 'joint will never fall apart again. And thar it is, thinking you could hang another car on that pipe now, all tucked up nicely inside the tunnel, and you couldn't even scrape that pipe on a trailer ramp now.

Next issue is to get the battery properly secured. Needed to cut more ready-rod an inch longer, double nut it to the floor, drop on the plastic battery box, drop in the battery and install the hold-down clamp. Also install the cables and the box cover. Safety tech will require the cable ends to be taped over, even through the box will be covered. Note to self, remember to install a web strap later to hold the cover in place.

A quick look at the Go-Pro camera mount on the roll bar. Tech requires a camera now, I suppose to know who to blame for an accident after the fact. This one is a tad too high, trying to look forward through the rear view mirror. And the bolts are too long and pointed in wrong direction, interfering with proper positioning of the camera. Another note to self, relocate the camera mount to the angle brace tube just below the main roll hoop. Enough for one day, plenty done today, and folks would like Sunday off, so we will take it up again come Monday.

A quick look at the Go-Pro camera mount on the roll bar. Tech requires a camera now, I suppose to know who to blame for an accident after the fact. This one is a tad too high, trying to look forward through the rear view mirror. And the bolts are too long and pointed in wrong direction, interfering with proper positioning of the camera. Another note to self, relocate the camera mount to the angle brace tube just below the main roll hoop. Enough for one day, plenty done today, and folks would like Sunday off, so we will take it up again come Monday.

Sunday - February 2, 2025:

Busy posting photos and notes from Saturday's tinkering, updating inventory for parts used in the past week, and parts adding to the wish list for future order.

Monday - February 3, 2025:

Racing Rabbit not track ready yet. Using small heat gun to remove"HP" lettering (H-Production) from the side, as it is to be registered in "ITC" (Improved Touring). Repairing a vapor vent hose on the fuel cell.

Tightening bolts at inboard end of the front drive halfshafts. Topping up oil in the gearbox.

Replacing a missing brake cooling hose, fixing loose screws in a tail light, get brake lights to work, discover failing tail light switch (add to shopping list)? I thought this was Bosch electrics, not Lucas. Lots of progress in the last few days, getting close now. Looks like the big spenders are about to go for 25 gallons of race fuel. Will be loading the race trailer on Thursday, planing Friday PM departure for Sebring International Raceway. Looks like we just got signed up as part of the pit crew. Well, something that MGA Guru should do once. Never been to Sebring before.

Tuesday - February 4, 2025:

Lots of time for not much benefit maybe, but I keep adding new Part Numbers pages as questions arise. This time for the threaded studs and nuts securing the exhaust pipe to bottom end of the exhaust manifold.

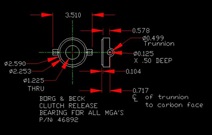

And another Part Numbers page for the 7H3214 carbon clutch release bearing. And another Part Numbers page for the 7H3214 carbon clutch release bearing.

Wednesday - February 5, 2025:

Adding more Part Numbers tech pages. This one is for the ACH5703 and ACH5704M nylon "plugs" that fit between brake drums and steel disc wheels on an MGA, while allowing screwdriver access for brake adjustment. Most disc wheel drum brake MGA have been missing these parts for decades with no detrimental effects.

Thursday - February 6, 2025:

Thursday - February 6, 2025:

Updated a tech page in the Body tech section for mounting a North American style license plate on the front of an MGA.

Friday - February 7, 2025:

Typical Friday morning at Tech Central with about a dozen people, tinkering on a couple of cars.

A TR6 needing a bit of tune up help,m and looking for some fasteners to re-attach a C tail light.

The Corvette still trying to remove the failed ABS module to repair a perforated brake pipe. From 8 bolts, 4 nuts came off, three studs broke,and one stud was spinning loose in the fiberglass floor. Get the grinder with abrasive wheel to cut off the last bolt.

No more work today, as it was loading and departure day for the racing Rabbit on its way to Sebring for the weekend. Lunch break was a little early, most folks done by half past noon. The Rabbit was all boxed up, and we were off shortly after 1-pm.

One pit stop in Lake Placid, pick up some snacks and arrive at Sebring International Raceway before 4-pm. Kick the Rabbit out of the trailer, unload the racing supplies, and get the car over for its annual tech inspection. Only one minor issue when the engine didn't stop running when the master kill switch was switched off. Oops. Bonnet off, and just a minute to disconnect one errant wire to make it work well enough to pass inspection. Racing suit, helmet, seat belts all up to date, and the car was certified good to go for another racing season. Back to the pits to reconnect the alternator wire on the correct terminal, and the important stuff was done for the day.

Saturday - February 8, 2025:

Some common central Florida fog delayed the start by an hour or so, as the track workers have to be able to see from one corner station to the next . First up were the small Formula cars and a few sport racers in Classes 1 and 2.

As soon as those were on the track it was time to line up group 3, including the racing Rabbit.

The Rabbit was out there strutting his stuff, running very nicely. After a few laps the driver decided to haul it in, as all he needed to know was that the car was running well and definitely ready to race.

Out for the second time just after lunch break at 1-pm. This would be the qualifying race to determine starting positions in he final race, so time to get serious. Everything was going well for 3 or 4 laps when spotter called driver on the radio with info that the next car in his class was running ten seconds slower per lap. With his starting position cinched, driver decided to haul it in, with no sense burning more fuel and wearing out the car any more than necessary. Back in the pits, while reviewing lap times, it was discovered that the "second" car in his class was actually part of a second faster for his fastest lap in qualifying. Oh well. We never did figure out if spotter made a mistake, of if the other car got much faster for his last lap or two. No biggie? It just means being staged one position farther back for the start in the final race.

The Rabbit was caged in impound for few minutes after leaving the track,as they were check weighing the cars. Looks like it was getting within a few pounds of the minimum weight limit, and for sure it would use more fuel in the longer race tomorrow. So driver and spotter headed into town to buy another 10-pound weight for the rabbit while they were also loading up the fuel cans. Navigator and I were off to find a good WiFi spot for the rest of the evening.

Sunday - February 9, 2025:

8-am staging for group 3, heading out for 15 minutes allowance for warm up and testing, just in case you changed or fixed anything from yesterday, get out there and verify that it works. Rabbit was doing well, so I think it came in a lap or two early. All other groups got their 15 minute warm ups in by a little after 11. Pushing a bit ahead of schedule today, group 1 was immediately out for their final 30 minute race, followed by group 2 at ten to noon, finishing around 12:20.

After a tight 1-hour lunch break, group 3 was on stage at 1:20-pm. That was when I finally figured out the dark blue#31 modern Mini was the other car in H-Prepared class. Blow the whistles and let them race for 30 minutes.

It was jolly good fun for about 10 laps, but with a couple laps to go the Rabbit dropped off the throttle and seemed to slow down a bit just before the Start/Finish line.Followed around the 180 bend and back on the second straight, a little off the pace but still running.

Given a couple of minutes, he came around the last turn an cruised down pit lane, heading for exit and back to the pits. Bummer. The story was, shifter problems. Finally found 3rd gear and left it there until it was back to the paddock. It was running and driving okay otherwise,so hopefully something minor.

We did injure the driver slightly getting him out of the car, scarfing his ankle on the window net hardware. Race day over, after a short breather it was time to pack up the toys and roll the Rabbit into the trailer for the trip home, blissfully uneventful.

Monday - February 10, 2025:

I thought I had an appointment with an MG Midget with electrical issues, but that was put off until next Saturday. After a busy week end there was lots of catching up to do with the photos and notes. I don't know if Jerry was looking at the Rabbit's shift linkage, but I don't think it's urgent. Good to be sitting down for the day.

Tuesday - February 11, 2025:

Composing a new Part Numbers tech page for AUC8170 Needle and Seat Assembly for carburetor float valves (work in process).

-- Still looking for a few used parts for the MGA, 1. A steel oil pipe for oil filter to engine block, 1956-1967, and 2. the mating banjo bolt, 3. a water pump pulley for MGB 1962-1967, 4. two aluminum air filter adapter plates for MGB 962-1974. The guy with the family parts yard who should have these parts has not been returning phone calls. -- Just changed a failed flasher unit (again). Found failed contacts in the fuse block, which we have in hand and expect to change tomorrow (among other things).

Wednesday - February 12, 2025:

Got busy and didn't get to work on the car today. Posting a few new Part Numbers pages for MGA door hinges,

AFH1494 for early right side 75-deg opening,

AFH2805 for early left side 75-deg opening,

AFH5832 for both sides 85-deg opening in later production. The changes happened in mid year 1958 production. These hinges must always be used in matched numbers for top and bottom on one door so that both hinges will stop at same angle for best strength, least tress.

Thursday - February 13, 2025:

We dropped into Tech Central today, as they are sometimes doing odd jobs on Monday or Thursday. Caught them playing with a new toy, a portable electric powered pressure washer. Just good to be able to clean cars and other things occasionally. And we had a few odd things to do on our car. The door seals we replaced, or tried to install some months ago, were a problem from the first day. Non-original in all materials and configuration, the installation did not go well. The steel spine didn't fit well over three layers of metal along bottom of the door opening, and the rubber edged furflex was not staying attached to the spine. Before throwing it out to try again with new parts, we were taking one feeble shot at trying to save this one. Spent some time trying to straighten the spine segments well enough to fit over the steel flange, then lined the flange and spine with black RTV sealant, and taped the furflex in place to see how long it might stay there. Time will tell.

Meanwhile the guys were playing with Tina, the wanna-B race car. Somehow they had managed to weld a quick release steering wheel adapter backward onto the steering column, so now they were grinding out the weld to do over.

And they were welding up holes in the door skin where a mirror had been removed. Follow with some grinding, Bondo, sanding, spot putty and primer. The DA sander should make short work of surface finish good enough for a race car.

One other small job for the MGA, replacing the corroded fuse block. That one has been in service since end of first restoration in 1986, so it doesn't owe us anything. Just that the current replacement part seems to be much lower quality, so no idea how long that will last before giving more problems.

Friday - February 14, 2025:

Friday with good weather brings out a crowd at Tech Central. The Corvette with leaky brake pipe and failed ABS is gradually progressing. Brake pipes were cut to lift out the ABS unit, still needing to remove screws to unplug the cable connector, and one more bolt still being stubborn.

The racing Rabbit was rolled out of the transport trailer and into the shop. Planning to drain/change engine oil, and remove the gearbox to fix the jammed in place gear 3rd gear. This is a well known and common phenomenon, and the fix is also well known. Nothing mysterious there, just some grunt work ahead.

Guys were wire wheel buffing a TR6 wheel to install a low profile tire for use as a space saver spare. No paint or balancing required, just install a new tire and toss it in the car.

The same TR6 was getting a new fuel filter installed. And some activity tossing out some junk, cleaning pavement, relocating furniture to move a work bench and add some new table and bench space (getting more organized).

There was a late arrival trying to steal the show. This is a rare car almost no one has ever seen, and normally only ever seen at some exclusive car show. It is 1996 Toyoda (yes it is spelled correctly with the "d"). Sorry, I don't recall the model number, but it is a one-year-only car with only 100 units built for the Japanese home market only. Original sale price was about $100,000-USD thirty years go, and it is a very nice car to match the price line. Power brakes, automatic transmission, no air bags.

Tina the MGB Wanna-B race car was getting some TLC today with a touch of filler and sanding. By day's end it would have a fresh coat of primer, and be all one color for the first time in many years. It must be progress.

Seems like the club is attracting attention and picking up s few new members. We have an appointment tomorrow to visit a young fellow (college kid) and his father to see about fixing a few electrical issues, turn signals, tail lights and such. Some guy we just met is a school teacher, about to retire in a couple years, intending to procure his lifetime dream of a Jaguar E-Type. Another bloke we have met before has a local car shop. and wants us to drop in sometime soon to check out his place, and maybe cast aspersions on a few cars in process. Still waiting for that appointment.

Saturday - February 15, 2025:

We had a serious appointment today with James Sr. and James Jr. in Naples FL. J Sr works days while J Jr is a college student, so we set aside time to meet them on the week end. Sr has owned this 1972 MG Midget with a Weber downdraft carburetor for a couple years, while Jr has an avid interest and has been driving the car some. Last time it ran may have been a month ago, while last fresh refueling may have been 3 months old. Today it wasn't starting, but they did have it on a battery charger. The fuel pump did run, but engine did not start. Spark for #1 plug seemed weak, but spark direct from the coil HT wire was very healthy. So we gave it a sniff of ether, and it fire up for a few seconds, so must have fuel starvation. -- Disconnect the fuel hose at carburetor, switch on to run fuel pump, but no flow. Maybe just not priming the pump, so get bold and suck on the hose a bit, and it did begin to pump a little air. Have patience, and soon it was pumping more air, and finally it was spurting out fuel. Reconnect the hose, switch on, listen while the carburetor would gurgle for a several seconds while filling with fuel, then all stop.Give it a crank and get an occasional pop, a few times, still no go. pumping the throttle did not help. Give it a sniff of ether, and then it fired up and ran. Likely stale fuel, but we certainly know what to do for that problem, if it persists. -- Once it warmed up we could down down idle speed a bit. Any quick poke at the throttle would result in cough, pop and die, so for sure the accelerator pump is kaput and needs a new rubber diaphragm, add that to the next parts order.

Then we were on to electrical problems. Headlights work on both high and low beams, a pleasant surprise. One front parking light light would glow only dimly, and only with headlights on, so pretty good bet the lamp fixture has failed ground. Remove lens, remove bulb, find totally dark grey bulb, toss it out and install a new bulb, but no change of function. Start future wok list with cleaning all of the electrical connections. -- Then use a jumper wire to connect power across the fuse block from battery input to other fuses output clips. We managed to get the tail lights end license plate lamps to light up, so verify some of the wiring is still good. Without the jumper wire, no side lamps at all, so the fuse block is badly corroded. They do have new fuse block, so put that at top of the work list. Jumper power to the green wire fuse output, step on the brake pedal, no brake lights, and a so no turn signals. Brake light switch looks like crap, may or may not work. Flasher units and turn signal switches are notorious for failure (nut not always). Midget parts used to be cheap, not so much any more, and the lamp fixtures are now over $50 each. So more diagnostic work is needed, and maybe some sweat-equity for cleaning contacts before throwing money at parts. -- We spent some time with a parts catalog, and time to find a wiring diagram on-line, and more time discussing strategy. It got to be dinner time, and people had other commitments, so knock it off for now and think about when we might make another appointment to resume. After getting these photos and notes in order, I need to send an email with more recommendations. Will need to spend another work session with these guys on test lights, jumper wires and diagnostics.

|