TechTip #8

Brake adjustment

MG drum brakes do not automatically adjust as the friction material wears down. This has to be done manually. If it is not then over time the brake pedal travel increases and the handbrake lever has to move higher to lock the rear drums and hold the car. So, letís take a deeper look at how disc and drum brakes work and when to adjust the handbrake. MG drum brakes do not automatically adjust as the friction material wears down. This has to be done manually. If it is not then over time the brake pedal travel increases and the handbrake lever has to move higher to lock the rear drums and hold the car. So, letís take a deeper look at how disc and drum brakes work and when to adjust the handbrake.

Disc brakes do automatically compensate for pad wear. They don't have springs to pull the pads away from the discs. When you take your foot off the brake pedal the fluid in the system returns to the master cylinder and the removal of fluid from the piston cylinders retracts the pistons away from the discs. The amount of retraction is controlled by the volume of the master cylinder and so is constant. As the pad wears the fluid level in the master reservoir will drop over time as more fluid remains in the piston cylinders. Disc brakes do automatically compensate for pad wear. They don't have springs to pull the pads away from the discs. When you take your foot off the brake pedal the fluid in the system returns to the master cylinder and the removal of fluid from the piston cylinders retracts the pistons away from the discs. The amount of retraction is controlled by the volume of the master cylinder and so is constant. As the pad wears the fluid level in the master reservoir will drop over time as more fluid remains in the piston cylinders.

On the other hand MG drum brakes don't automatically adjust for wear. Some cars, particularly more modern ones, do On the other hand MG drum brakes don't automatically adjust for wear. Some cars, particularly more modern ones, do

| |

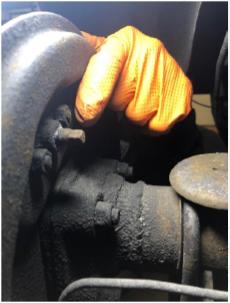

Square-headed wrench for brake adjustment

|

compensate and thus there can be some confusion between the two types. The drum brakes have springs to pull the shoes away from the drums when the hydraulic pressure is removed, so they move back to the same place every time. Thus if the shoes arenít adjusted the pedal travel increases with wear as the brake wheel cylinder pistons have to travel further for the shoe to make contact on the drum. The handbrake will also loose effectiveness and the lever will have to be pulled higher to engage the shoes onto the drums.

Square headed 'bolt' on back of brake plate

|

|

On my MGB GT, the adjustment is done by screwing into the back plate a square headed 'bolt'. To do this you must use the square-headed wrench. Trying to use an open ended wrench or adjustable wrench is asking to round off the square end of the adjuster and create a whole new world of hurt for you and your pocket book! The good news is that the adjuster assembly on a B is replaceable if this happens (or if it totally seizes up which is not uncommon). Either side of the adjuster you can see two nuts, these can be removed to replace the adjuster which is on the other side of the back plate along with the shoes, springs etc. MG Midget owners can't do this because the adjuster assembly is part of the back plate and not removeable. So the back plate has to be replaced and it's not available new .................. Beware! On my MGB GT, the adjustment is done by screwing into the back plate a square headed 'bolt'. To do this you must use the square-headed wrench. Trying to use an open ended wrench or adjustable wrench is asking to round off the square end of the adjuster and create a whole new world of hurt for you and your pocket book! The good news is that the adjuster assembly on a B is replaceable if this happens (or if it totally seizes up which is not uncommon). Either side of the adjuster you can see two nuts, these can be removed to replace the adjuster which is on the other side of the back plate along with the shoes, springs etc. MG Midget owners can't do this because the adjuster assembly is part of the back plate and not removeable. So the back plate has to be replaced and it's not available new .................. Beware!

On earlier cars, like MGAs the adjustment of the brake shoes is done from the other side, through a hole in the drum. You use a flat-bladed screwdriver to rotate a cam that moves the shoe towards or away from the drum. In this case you may be able to get access to the hole in the drum through a wire wheel but disc wheels will almost always need to be removed. As the car needs to be jacked up and on stands so the drum can be rotated is usually easier to remove the wheels and tyres anyway. On earlier cars, like MGAs the adjustment of the brake shoes is done from the other side, through a hole in the drum. You use a flat-bladed screwdriver to rotate a cam that moves the shoe towards or away from the drum. In this case you may be able to get access to the hole in the drum through a wire wheel but disc wheels will almost always need to be removed. As the car needs to be jacked up and on stands so the drum can be rotated is usually easier to remove the wheels and tyres anyway.

In both types adjust the shoes until they are tight on the drum and the drum wont rotate. Then gradually back off the adjustment until the drum will rotate reasonably freely. Expect some 'kissing' of the drum on a shoe as it rotates because everything isn't perfectly round and centered. If the drum rotates totally freely (no 'kissing') the shoes have been backed away too much. In both types adjust the shoes until they are tight on the drum and the drum wont rotate. Then gradually back off the adjustment until the drum will rotate reasonably freely. Expect some 'kissing' of the drum on a shoe as it rotates because everything isn't perfectly round and centered. If the drum rotates totally freely (no 'kissing') the shoes have been backed away too much.

Once the rear brake shoes have been adjusted then, and only then, can the handbrake be checked. Obviously all the brake shoe adjustments must be done with the handbrake off, i.e. the lever all the way down. To check the handbrake now pull the lever up, counting the number of clicks until it wonít move up any more. You should have between 4 and 6 clicks, so +/-5 in other words!! Too many and the handbrake may not hold the car on a slope, too few and the handbrake may be holding the shoes on or too close to the drum so they are binding. The handbrake cable can now be adjusted if needed. With the lever as high as you can get it the drums should be locked and unable to rotate. The cable adjustment is done at the bottom of the lever in the transmission tunnel on MGAs, Bs and Midgets. Once the rear brake shoes have been adjusted then, and only then, can the handbrake be checked. Obviously all the brake shoe adjustments must be done with the handbrake off, i.e. the lever all the way down. To check the handbrake now pull the lever up, counting the number of clicks until it wonít move up any more. You should have between 4 and 6 clicks, so +/-5 in other words!! Too many and the handbrake may not hold the car on a slope, too few and the handbrake may be holding the shoes on or too close to the drum so they are binding. The handbrake cable can now be adjusted if needed. With the lever as high as you can get it the drums should be locked and unable to rotate. The cable adjustment is done at the bottom of the lever in the transmission tunnel on MGAs, Bs and Midgets.

Steve Skegg

Technical Coordinator

Photographs courtesy of Michael "Spitfire" Stuart.

|