The MGA With An Attitude

DRIP RAIL Rivets and Sealing - CP-122

For sealing of the drip rail bright trip piece over the door opening, there was originally some thin black sealant, most likely dried hard and not to be re-used if/when this part is ever to be reassembled. This sealing material was likely similar to Eldro Dum Dum sealant (the product name seems to be uniquely British). That product is a soft putty that is supposed to remain pliable "indefinitely", but after a few decades it can go hard and brittle. It is commonly applied to spot welded body joints after spot welding but before painting, mostly intended to keep water out of the interior of the car. It may be found along joints in a steel floor pan or boot floor, and at joints where inner fenders are welded to the top body cowling where outer fenders will attach (but not on the outer fender joints when bolted).

For sealing of the drip rail bright trip piece over the door opening, there was originally some thin black sealant, most likely dried hard and not to be re-used if/when this part is ever to be reassembled. This sealing material was likely similar to Eldro Dum Dum sealant (the product name seems to be uniquely British). That product is a soft putty that is supposed to remain pliable "indefinitely", but after a few decades it can go hard and brittle. It is commonly applied to spot welded body joints after spot welding but before painting, mostly intended to keep water out of the interior of the car. It may be found along joints in a steel floor pan or boot floor, and at joints where inner fenders are welded to the top body cowling where outer fenders will attach (but not on the outer fender joints when bolted).

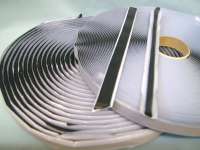

Use of silicone sealant (RTV) is a little bit risky here, as many RTV compounds contain an etching agent that could attack paint and cause corrosion of the underlying metal. Since the trim piece is quite thin, use of any sealant may glue it together well enough to make any future removal nearly impossible without damaging the trim piece. Use of a thin rubber strip from a bicycle inner tube might be feasible. If you want to use sealant here, a modern substitute for Dum Dum may be reasonable, like Flexible Strip-Caulk or 3M Fast N Firm caulking. Someone also found at Lowe's a light grey, non-silicone, forever flexible, lifetime caulk (apparently available in various colors).

Use of aluminum pop rivets is also risky, as dissimilar metals will encourage galvanic corrosion. It is best to use stainless steel rivets here. Install as many pop rivets as possible without crimping to ensure that the strip is aligned correctly. Starting in the center and working out toward both ends seems to work well.

|